Wicket Gate Servo Motor Refurbishment

Power House Unit 1 Wicket Gate

Servo Motor Refurbishment

Location: Butte County

Completed: February 2020

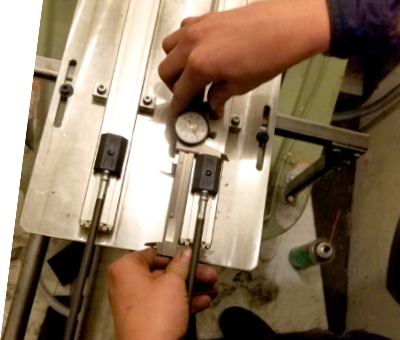

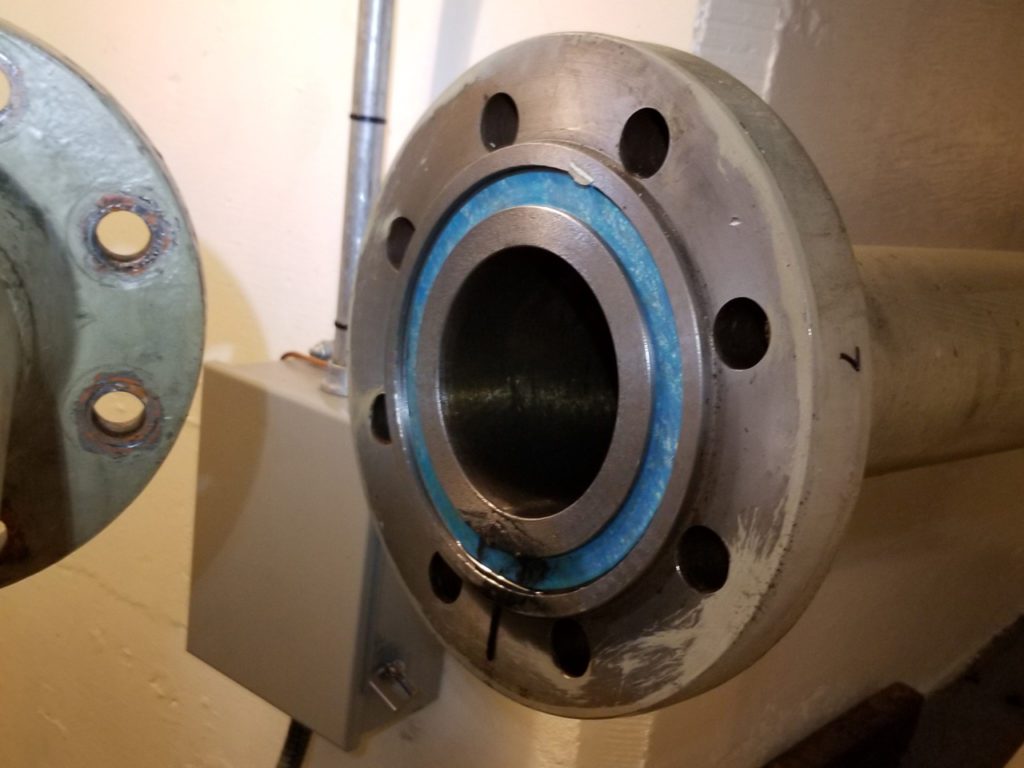

A longtime client of TCB contacted our Hydro Division about an excessive oil leak both internal and externally on the wicket gate servo motors. TCB jumped into action, performing as found alignment measurements of the wicket gate elevations and shutter clearances. It was determined that the wicket gate measurements were out of specification tolerances and would need to be corrected in parallel to the Servo refurbishment. TCB’s crew disassembled the servo motors and transported them to one of our trusted vendors for further, in depth disassembly and investigation. During this process we found that the piston rods needed new bushings and piston rings. In addition to that, the pistons themselves were cracked and deemed unusable. TCB along with Machine Shop fabricated two new heads, one for each servo.